Water pollution control is one of the major thrust areas of present scientific research.

The effluents generated from industries create major environmental problems and issues both in public and Environment. Industrial wastewater treatment is one of the major problems in the present scenario. Domestic and industrial wastewater detoxification is of vital importance for the protection of natural ecosystems and human health. Wastewater processing is usually performed in several steps, including physical, chemical and biological treatment. Biological treatment using aerobic activated sludge process has been in practice for well over a century. Increasing pressure to meet more stringent discharge standards or not being allowed to discharge treated effluent has led to implementation of a variety of advanced biological treatment processes in recent years. The use of microorganisms for the biodegradation of pollutant is an attractive alternative to the development of bioremediation processes for the treatment of wastewater. Biological methods are environmentally friendly, produce zero sludge than physical and chemical systems, and are relatively inexpensive, as the running cost is low.

Biological Wastewater Treatment

Microorganisms play a major role in decomposing waste organic matter, removing carbonaceous BOD, coagulating non settable colloidal solids, and stabilizing organic matter. These microorganisms convert colloidal and dissolved carbonaceous organic matter into various gases and cell tissue. The cell tissue, having a specific gravity greater than water, can then be removed from treated water through gravity settling.

Activated Sludge Process is the most common and oldest treatment process used to treat municipal and industrial wastewater. Typically wastewater after primary treatment i.e. suspended impurities removal is treated in an activated sludge process based biological treatment system comprising aeration tank followed by secondary clarifier. The aeration tank is a completely mixed or a plug flow (in some cases) bioreactor where specific concentration of biomass (measured as mixed liquor suspended solids (MLSS) or mixed liquor volatile suspended solids (MLVSS)) is maintained along with sufficient dissolved oxygen (DO) concentration (typically 2 mg/l) to effect biodegradation of soluble organic impurities measured as biochemical oxygen demand (BOD5) or chemical oxygen demand (COD).

Aerobic, as the title suggests, means in the presence of air (oxygen); while anaerobic means in the absence of air (oxygen). These two terms are directly related to the type of bacteria or microorganisms that are involved in the degradation of organic impurities in a given wastewater and the operating conditions of the bioreactor. Therefore, aerobic treatment processes take place in the presence of air and utilize those microorganisms (also called aerobes), which use molecular/free oxygen to assimilate organic impurities i.e. convert them in to carbon dioxide, water and biomass. The anaerobic treatment processes, on other hand take place in the absence of air (and thus molecular/free oxygen) by those microorganisms (also called anaerobes) which do not require air (molecular/free oxygen) to assimilate organic impurities. The final products of organic assimilation in anaerobic treatment are methane and carbon dioxide gas and biomass.

Bionics Enviro Tech, Tamil Nadu, India is a scientific manufacturer of microbial bacterial bio culture –NANOZYME to achieve Zero sludge and Zero pollutant in effluent treatment plant (ETP), Sewage treatment plant (STP), Anaerobic digester (AD), solid waste management (SWM), agriculture biofertilizers, lake bioremediation and aquaculture. Microbial NANOZYME are innovated by intensive research and development which suit specific needs of various industries.

What Is Nanozyme?

“NANO-ZYME” which are Effective Microbes (EM) contain multiple strains of aerobic anaerobic and facultative anaerobic microbes, which are selected for their compatible, symbiotic metabolic pathways based on different industrial effluent characteristics. Based on extensive R&D. Our bacteria and enzyme products are developed using bacterial strains which are very efficient for improving the purification process of industrial, municipal & residential wastewater. Each gram of product contains up to 62 different strains of bacteria. All the bacteria present in NANOZYME are highly stable. Nanozyme Products are manufactured with stringent laboratory standards incorporating modern equipment’s using scientific innovative formulas with ISO 9001-2015 standards and NABL accreditations for laboratories.

NANZOYME products are based on the latest advanced biotechnology designed to meet the requirements of specific waste water treatment problems. Bacteria break down organic matter into simple compounds like carbon dioxide and water, and they cycle important nutrients such as nitrogen, sulfur, and phosphorus. The enzymes enable the microbes to use the organic contaminants as sources of energy and/or as reproductive building blocks.

The Nanozyme products are using Dye Industries, Leather & Tannery, Paper and Pulp Mills, Chemical Industries, Pharmaceutical Units, Sugar And Distilleries, Food & Beverage, Breweries, Wine And Alcohol Plants, Automobile, Petro-Chemical, Pharmaceuticals, ETPs, STPs Common Effluent Treatment Plants (CETP), Common Sewage treatment Plants (CSTP) with separate formula. BIONICS products NANOZYME are very useful to help industrial community, municipal authorities, commercial and public properties. We carry out a vast amount of R&D work. Current focal points include zero sludge, COD, BOD, TDS, TSS, heavy metals reduction with low cost treatment of biological high-performance systems.

Merits Of Advanced Biological Treatment Technologies By Using Nanozyme

Biological wastewater treatment is often the most economical and eco-friendly alternative, relative to other physical and chemical processes.

- Zero sludge Process.

- Low Cost Treatment and Increases efficiency of the Effluent/ Sewage treatment plant and saves energy costs.

- Non-corrosive, non-pathogenic and low quantity use, making it safe and easy to handle and store.

- Results meet criteria for new Pollution Control norms.

- Seeding a new treatment plant with NANOZYME, to ETPs and STPs reduces the commissioning time to a great extent.

- No design or process modifications required.

- NANOZYME effectively treats the suspended and floatable organic debris.

- Reduction of Up to 95% in BOD & 90% reduction in COD load, TSS, TDS, Inorganic, organics and heavy metals.

- Reduction in chemical usage.

- Reduces the energy consumption especially reduce the aeration time and number of aerator (blower).

- Reduction in Color and odor of the effluent.

- Improved Anaerobic digester efficiency .

- Biomass performance even under high TDS.

- Combination of various strains will successively promotes the growth of bacterial population, break down and digest the waste in both aerobic and anaerobic conditions to a far greater degree than single microbial strain.

- Bacteria break down organic matter into simple compounds like carbon dioxide and water, and they cycle important nutrients such as nitrogen, sulfur, and phosphorus.

- The enzymes enable the microbes to use the organic contaminants as sources of energy and/or as reproductive building blocks.

- Bacteria can migrate to areas that are rich in specific nutrients that they require for growth. Bacteria can also attach themselves to surfaces and form communities known as biofilms.

- Biological treatment method is only real treatment method that can degrade the organic and inorganic pollutant/ waste present in the waste water.

- Bacteria’s are living organisms that continually adapt and grow in the system. They consume the waste, chemicals, medicals; they do not move it from one place to another.

- Our products are based on the latest advanced technology in biotechnology designed to meet the requirements of specific waste water treatment problems.

- Specially selected and acclimated strains of microorganisms supplied in NANOZYME microbial enzyme products produce millions of times the levels of organic digesting catalysts produced by wild type of microorganisms found naturally in various waste. With the bacterial product the content of the waste stream determines how many enzymes are produced, in what sequence, at what oncentration, and for what duration. The bacteria function as millions of tiny enzyme factories to produce the correct balance of degradative power.

How do bacteria break down any molecule?

Bacteria have the capability of producing many different types of enzymes that degrade a wide variety of organic materials such as fats, oils, cellulose, xylan, proteins starches and all chemicals. The polymers that must be reacted with more than one type of enzyme in order to be efficiently degraded to their basic building blocks. Bacteria can produce the complete “team” of enzymes that are necessary to degrade and consume the organic materials present in their environment at any given time. Bacteria can adapt to a range of conditions and food supplies. They can change the type of enzymes that they produce if the food source changes. They can protect themselves from changes in environmental conditions by forming colonies, biofilms, or spores.

How quickly do high enzyme producing bacteria and in what quantities?

Bacteria have the capability of producing many different types of enzymes. They are living organisms that respond to their environment. Nature provides a specific “team” of enzymes to attack each type of polymer. Production of enzymes begins as soon as the bacteria begin to grow. The cells must obtain nutrients from their surroundings, so they secrete enzymes to degrade the available food. The quantities of enzymes produced vary depending on the bacterial species and the culture conditions (e.g., nutrients, temperature, and pH) and growth rate. Hydrolytic enzymes such as proteases, amylases, and cellulases, etc. are produced in the range of milligrams per liter to grams per liter. Bacteria can grow very quickly, doubling their populations in as little as 20-40 minutes. In some applications, it is common to “boost” bacterial colonization. Bacteria’s can adapt and grow in various extreme conditions of pH, temperature and availability of nutrients as well as high concentrations of pollutant because of the high CFU counts (colony forming units)

Advantages of Microbial Nanozyme Product

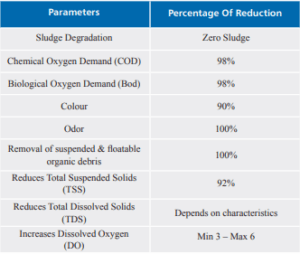

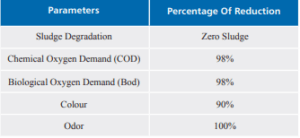

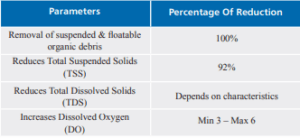

This microbial NANOZYME effectively treats the suspended and floatable organic debris. Reduces COD (Chemical Oxygen Demand), Reduces BOD (Biological Oxygen Demand), Reduces TDS – Total Suspended solids, TSS (Total Suspended Solids) Combination of various strains will successively promotes the 130 Water Today – The Magazine l May 2018 growth of bacterial population, break down and digest the waste in both aerobic and anaerobic conditions to a far greater degree

Microbial Nanozyme on Wastewater Treatment Plants

Bacteria can migrate to areas that are rich in specific nutrients that they require for growth. Bacteria can also attach themselvesto surfaces and form communities known as biofilms. Reduction of Up to 98% reduction in BOD & 95% reduction in COD load, TDS, Inorganic, organics and heavy metals. The quantities of enzymes produced vary depending on the bacterial species and the culture conditions (e.g., nutrients, temperature, and pH) and growth rate. Hydrolytic enzymes such as proteases, amylases, and celluloses, etc. are produced in the range of milligrams per liter to grams per liter. Bacteria can grow very quickly, doubling their populations in as little as 20-40 minutes. In some applications, it is common to “boost” bacterial colonization.

Microbial Nanozyme On Wastewater Treatment Plants

Dosage Details:

Dosage: 10kgs/ 100 KLD Effluent/ 2-3 Months. It will vary depends on COD, BOD and other parameters.

Important About Nanozyme

NANOZYME, when added helps to

- Population “ > 17 Million per milli gram” (17 x 10 -9).

- Sludge volume will be reduced more > 90 – 98%, as more solids are degraded.

- Fast Start-ups & Bacterial Oxidation of the phase will be faster and more complete.

- Effluent water standards will be met more consistently, helping to maintain a clean environment.

Article written by Dr. M. Parameswari Sasikumar Ph.D., AGRI., ENVIRO, Executive Director, Bioncis Enviro Tech, India.